Steinzeug-Keramo, a leading European manufacturer for wastewater infrastructure and a company of wienerberger, is highlighting the economic advantages of vitrified clay pipes in sewer systems following Life Cycle Costing analysis.

Independent research conducted by Project Hub 360 confirms that if the operational lifespan of a sewer system exceeds 40 years, vitrified clay pipes represent the most economically viable investment.

This finding challenges the traditional focus on initial costs, advocating for a more comprehensive approach to sewer infrastructure investment.

In some sewer systems, material selection is often driven by the lowest initial costs, but this approach can lead to higher long-term expenses in maintenance and potential replacement.

The methodology of Cycle Costing (LCC), which evaluates the total costs associated with a product or system over its entire lifecycle, is gaining momentum as the industry look for future-proofed systems.

The recent study by Project Hub 360 mapped the full lifecycle costs of vitrified clay pipes compared to thermoplastic alternatives for drainage and wastewater applications over a 150-year horizon.

Based on a completed project in Val Tinella, Italy, the analysis revealed that while the initial investment for vitrified clay pipes was €3,317,882 compared to €3,188,377 for polypropylene (+4%), the long-term savings achieved through reduced maintenance and replacement costs make vitrified clay the superior choice for utility companies looking to future-proof their sewer investments.

Tom Deckers, Managing Director at Steinzeug-Keramo, said: “Independent LCC research confirms that if the operational lifespan exceeds 40 years, which is the case with the vast majority of sewer systems, vitrified clay pipes are the best investment from an economic standpoint. Although clay pipes require a slightly higher initial investment of only around 4%, they offer cost savings of up to 65% in the long run compared to alternative materials.”

Tom added: “As the UK water industry looks for better long term value, adopting an LCC approach to product choice will help avoid unexpected expenses and enhance the sustainability of sewer infrastructure. By integrating the LCC methodology into decision-making processes, stakeholders can make informed choices that ensure maximum value from their investments.”

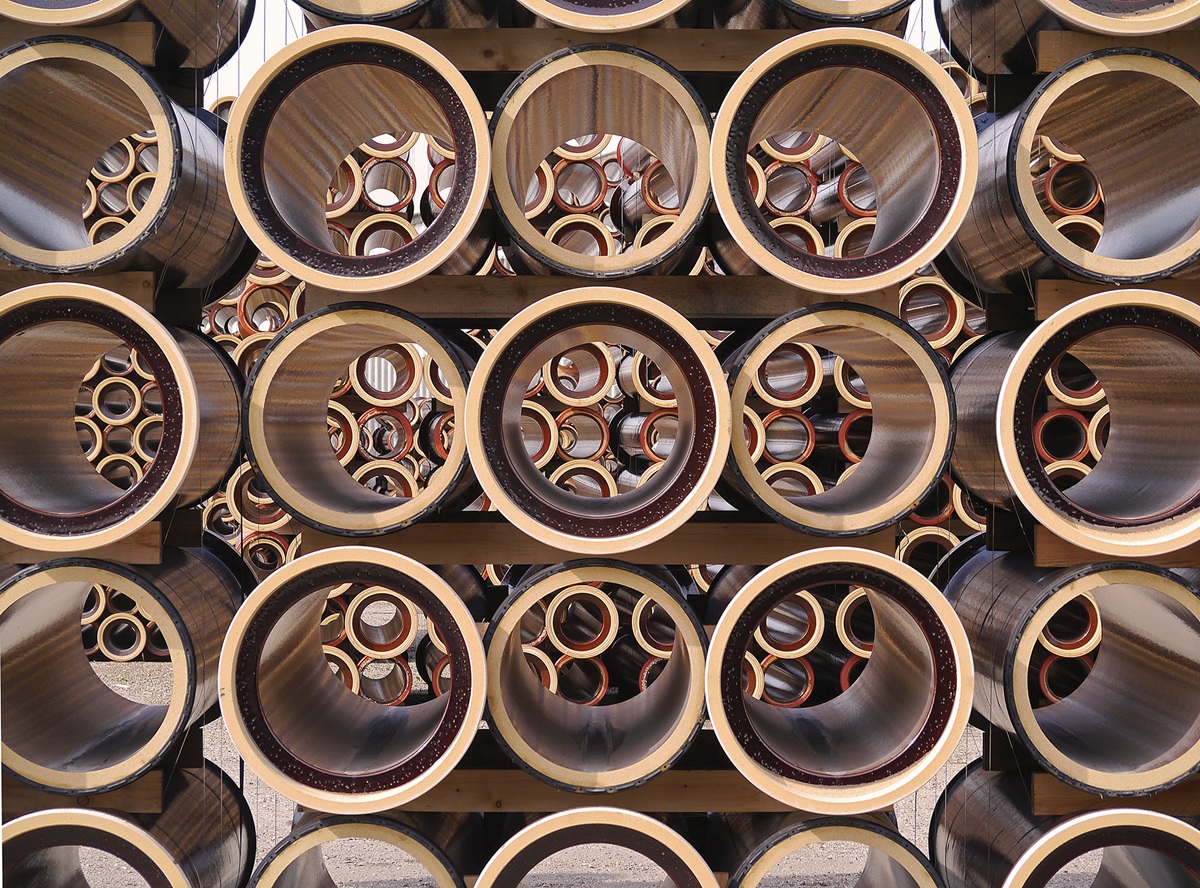

Steinzeug-Keramo´s products, which meet BS EN 295-1:2013 Vitrified clay pipe systems for drains and sewers, can be used for open trench, pipe jacking or sewer renovation and are available in diameters 100 – 800 mm, including DN150mm and DN225mm pipes and fittings with EPDM couplers that are compatible with Naylor Densleeve profiles.

Being impervious to hydrogen sulphide gasses found in sewer systems makes vitrified clay pipes suitable for environments where aggressive substances are present. Their chemical resistance ensures an ultra-longer service life, making them suitable for a wide range of challenging applications.

Steinzeug-Keramo vitrified clay pipes are inherently sustainable; they are made solely from natural materials like clay, chamotte and water, are 100% recyclable and boast a lifespan that can exceed 150 years.

Contractors can source Steinzeug-Keramo´s vitrified lay pipes from select stockists around the UK.

For more information on Steinzeug-Keramo, click here